CRUSHING & SCREENING

Superior Industries manufactures portable and stationary processing and handling equipment for dry bulk material industries such as construction aggregates, mining, concrete, asphalt and recycling industries. The company markets its equipment globally, both directly and through a network of dealers. Superior manufactures equipment for crushing, screening, washing, feeding and conveying at its head office Morris, Minnesota and satellite plants in Columbus, Nebraska; Prescott Valley, Arizona; Loganville, Georgia; Pekin, Illinois; Calgary, Canada; and Miramichi, New Brunswick.

Like its equipment, Superior’s conveying components serve a variety of industries like construction aggregates and mining. Components are sold through a large, global distribution network. Outside of distributor territories, the company sells its product directly to customers. Products include idlers, pulleys, belt cleaners and conveyor related accessories. Conveyor components are manufactured in Morris, Prescott Valley and Loganville.

In 2016-17 Superior debuted a brand of new group of crushing, screening and washing equipment after completing several acquisitions and in-house design projects. These products complimented the existing and evolving conveyor and custom plant portfolio to make a complete offering from ROCK FACE TO LOAD OUT®

Liberty® Jaw Crusher

- Production up to 1,595 TPH (1,450 MTPH)

- Feed opening up to 59” x 78″ (508×1,397mm)

- Feed size up to 47” (1,200mm)

Patriot® Cone Crusher

- Horsepower up to 600 HP (450 kW)

- Head diameter up to 59” (1,500mm)

- Feed opening up to 14” (356mm)

Valor® Vertical Shaft Impactor (VSI)

- Gear and belt drive models

- Production up to 600 TPH (550 MTPH)

- Feed size up to 8” (203mm)

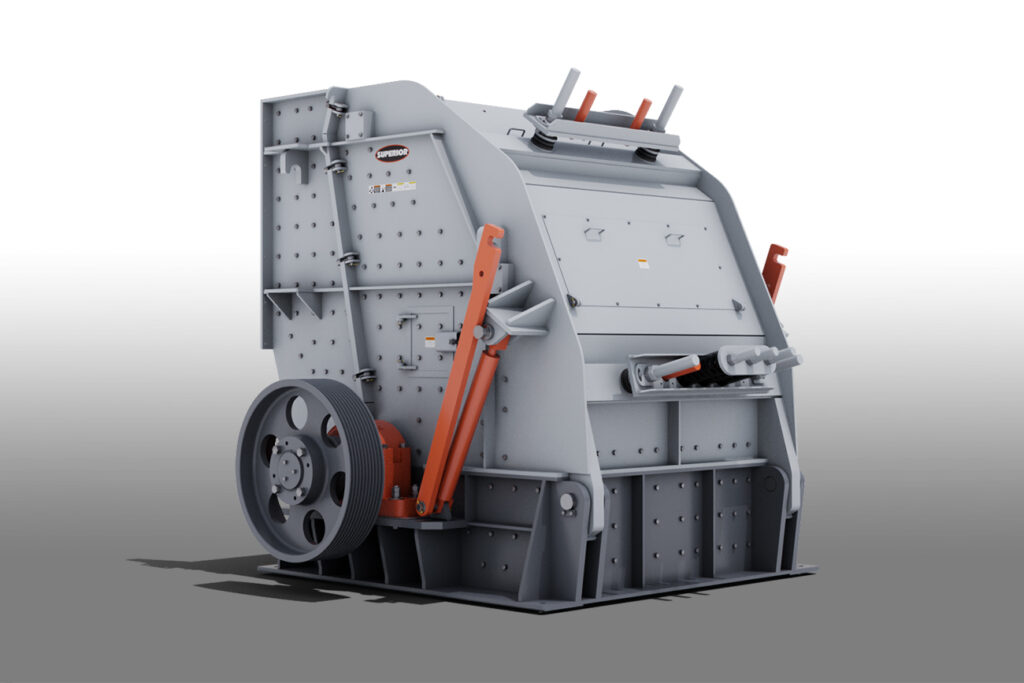

Sentry™ Horizontal Shaft Impactor (HSI)

- Production up to 990 TPH (900 MTPH)

- Feed opening up to 85” (2,150mm)

- Feed size up to 39.4” (1,000mm)

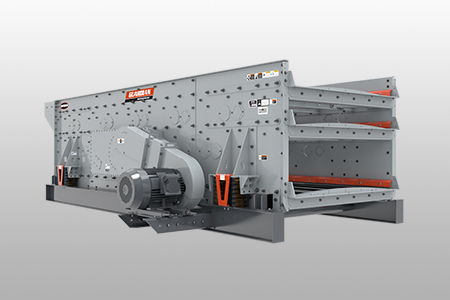

Guardian® Horizontal Screen

- 5×16, 6×20, 7×20, 8×20 (feet)

- Two or three decks

- Triple shaft, oval stroke

Anthem® Inclined Screen

- 5×16 – 8×24 models

- Two, three or four deck configurations

- Bottle jack lifting points

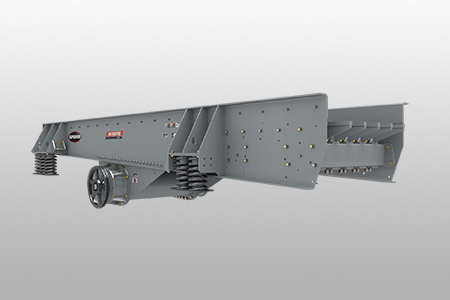

Intrepid® Vibrating Grizzly Feeder (VGF)

- 340 TPH – 1,400 TPH

- 36 in. – 60 in. pan widths

- Horizontal or 5 degree incline

Drop us an Enquiry

Fill in the form below with your requirement. One of our experts will assist you shortly.

Grab our stocklist now!

© 2018 All rights reserved

Address

SINGAPORE(HQ)

05-17, International Plaza,

10 Anson road, Singapore

OFFICE

5001 Beach Road #09-96, Golden Mile Complex, Singapore 199588

AUSTRALIA

11/288 Amherst Road,

Canning Vale WA 6155

CONTACT

GLOBAL TEL

+1 201 490 0206

SINGAPORE

+65 81596302

AUSTRALIA

1300 KEEP MINING (1300 533764)

GLOBAL TEL

+1 201 490 0206

SINGAPORE

+65 81596302

AUSTRALIA

1300 KEEP MINING (1300 533764)